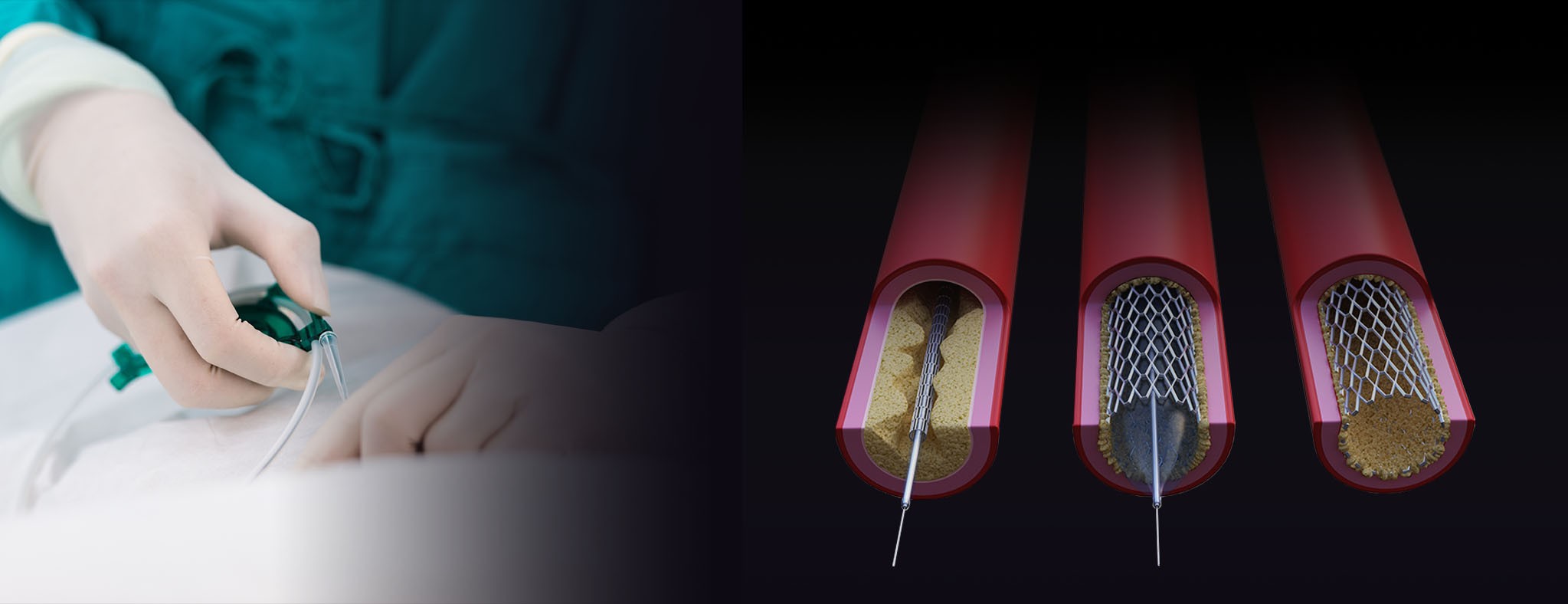

AMP and its partners bring the latest technologies in microfabrication such as Electric Discharge Machining, Class-7 cleanroom manufacturing, and assembly. Our capabilities include precision CNC, milling, drilling, and threading with end mills as fine as 0.1mm, which is finer than the average human hair thickness of 0.7mm. We provide extensive expertise in microfabrication and a wealth of experience in high-speed rotary machining with small scale tooling. Our manufacturing fulfills the precision needs of industries with versatile microfabricated components such as micromotors, bearings, medical devices and implants, precision equipment, robotics, communication, aerospace, semiconductors, etc.

In the field of thin wall processing, AMP possesses the capability to fabricate ultra-thin walls with a thickness of only 0.035mm. This high-precision thin-wall processing is subject to deformation caused by residual stress in the material and the heat generated during the process. Therefore, specialized manufacturing expertise is essential. Leveraging the extensive experience it has accumulated, AMP has attained remarkably high precision and geometric tolerances, even in the production of precision components with thin walls that are challenging to manufacture.

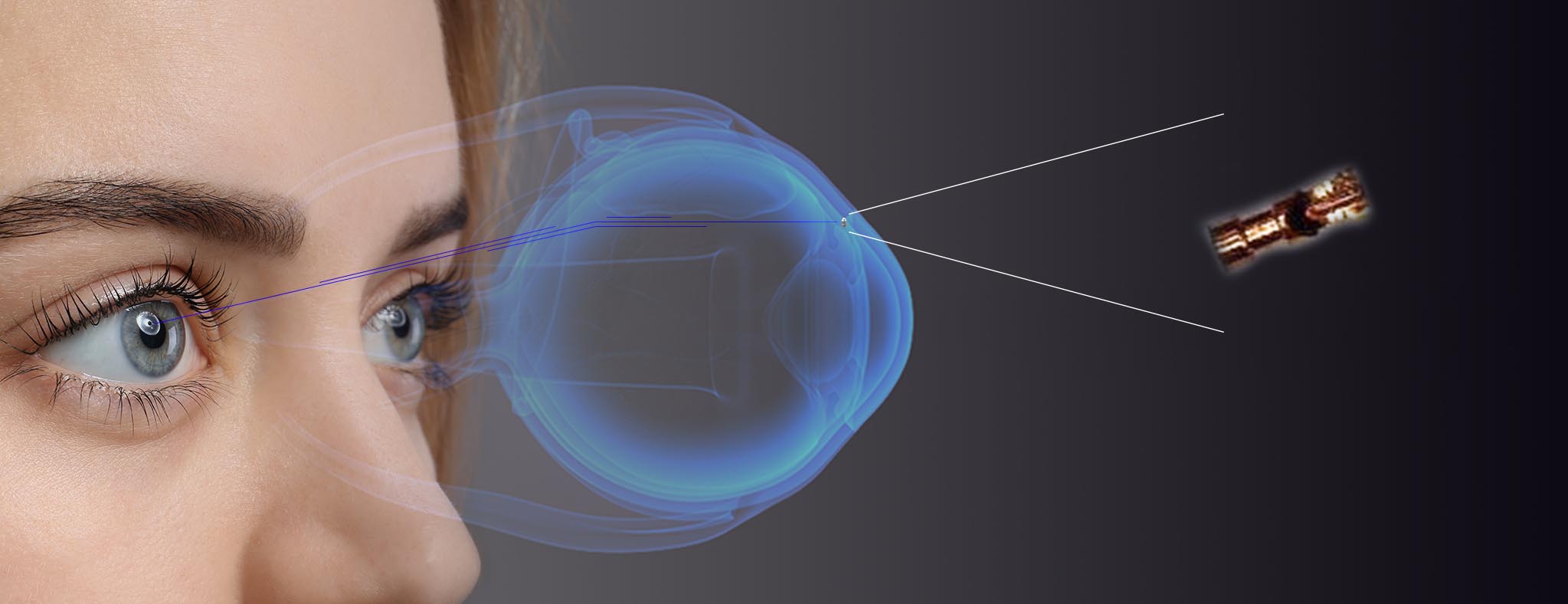

With the introduction of the femtosecond laser, AMP now has the capability to cut exceptionally fine features as small as 5 microns. The ultra-short pulse duration and frequency of the femtosecond laser enable cutting with minimal thermal impact, ensuring clean and precise edges that far surpass those achieved with standard laser cutting techniques.

By making full use of the state-of-the-art CNC compound automatic lathe that can integrate turning and machining with one chucking, we can handle complicated and specially shaped products that require multiple processes with high accuracy and short delivery time. With an outer diameter of φ200 or less, we specialize in processing with strict geometrical tolerances, same myocardial grain processing, detailed surface roughness instructions, sealing surface, mirror finish, etc. Even after heat treatment, we have a multi-axis (4-axis) grinding machine and a matching grinding machine, so it is possible to handle high-precision fitting and strict finished surfaces with one chucking.

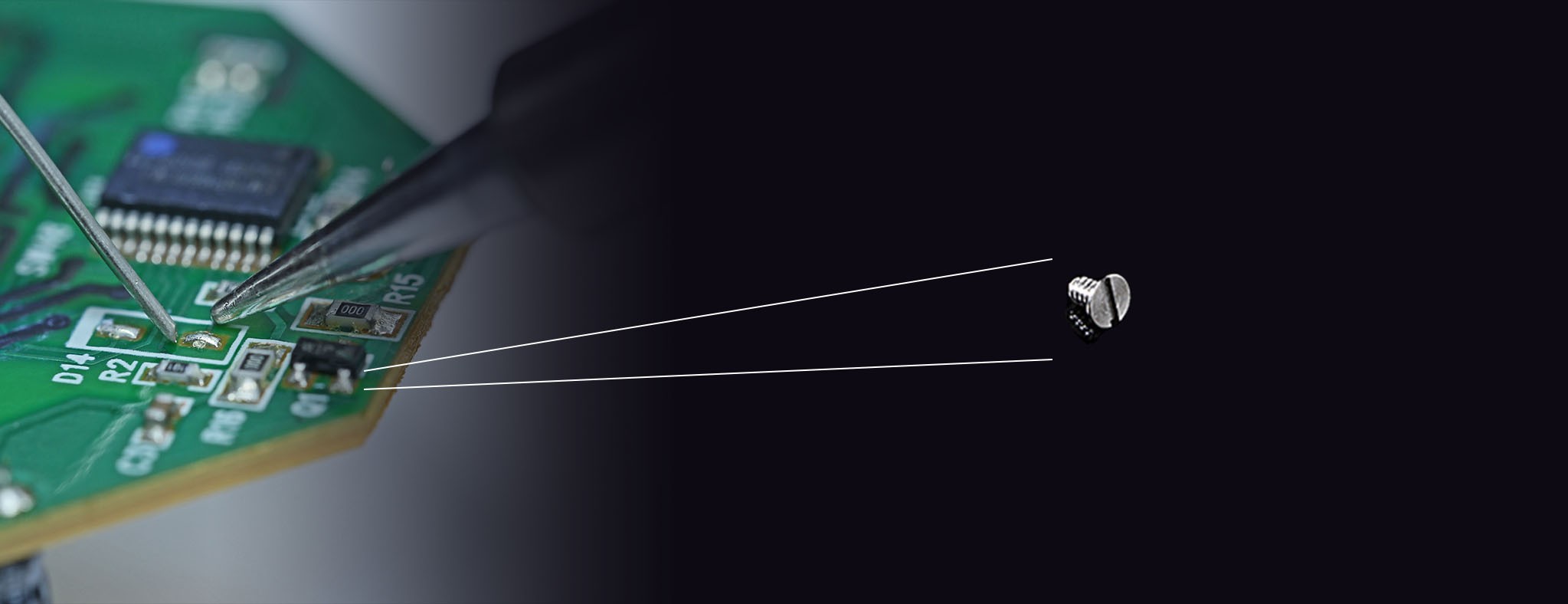

With Wire Electric Discharge Machining (EDM), AMP provides a complementary precision tooling solution that utilizes a wire with a diameter of 0.1mm for cutting. Wire EDM excels in crafting the most intricate and complex designs with supreme accuracy, ensuring high quality without compromise.

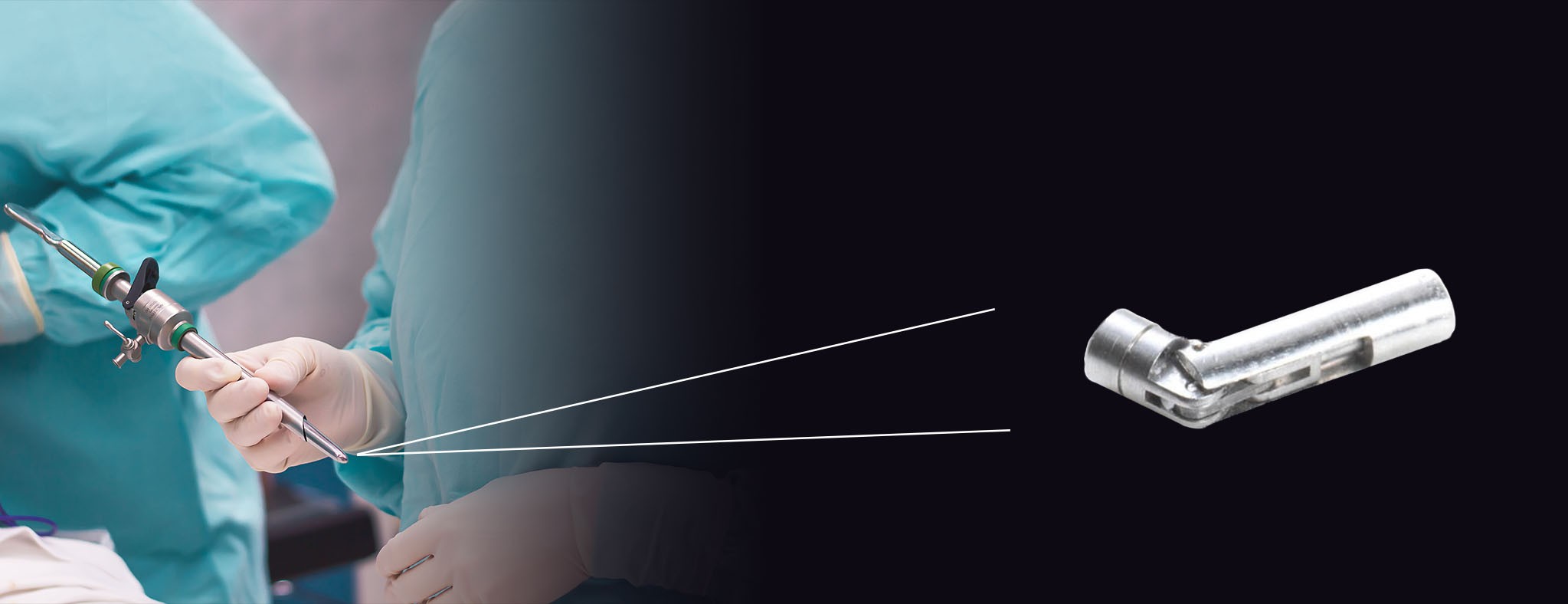

Utilizing Swiss CNC technology, also known as Swiss Lathes, AMP combines the turning capabilities of a lathe with the machining precision of CNC in a single operation. This integration restricts the movement of components between machines, offering our customers increased accuracy and reduced costs associated with jigging. AMP specializes in the automated production of small, implantable devices, employing machines exclusively dedicated to the manufacturing of implantables.

Our Verification and Validation (V&V) process ensures thorough testing and validation of products throughout design and manufacturing, including 100% inspection process for clients needing additional assurance. This rigorous approach involves inspecting all critical components, systems, and final products to meet specifications and performance criteria. By adhering to strict inspection criteria and continuously improving our processes, we deliver high-quality products that meet or exceed customer expectations, ensuring the highest standards of quality and satisfaction.