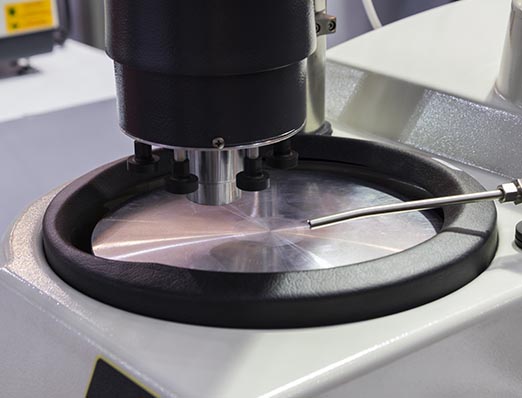

Advanced Micro Precision, “AMP” works with ISO 9001 / ISO 14001 / ISO 13485 Certified and Class ISO-7 Clean Room enabled specialists that produce unique and precise parts that are tailored to meet the sophisticated design needs of industry leaders in the medical device, micro electronics, and semiconductor industries. All parts are produced in carefully selected Japanese factories that are capable of highly customizable solutions on the sub-micron scale, while maintaining the highest levels of quality standards. AMP facilitates the design, customization, inspection, measurement, and timely delivery of your parts. We are with you every step of the way, including the audit process, to ensure your parts meet rigorous internal and external quality control standards. If you have a design need that requires complex shapes or extreme miniaturization, please do not hesitate to contact us.

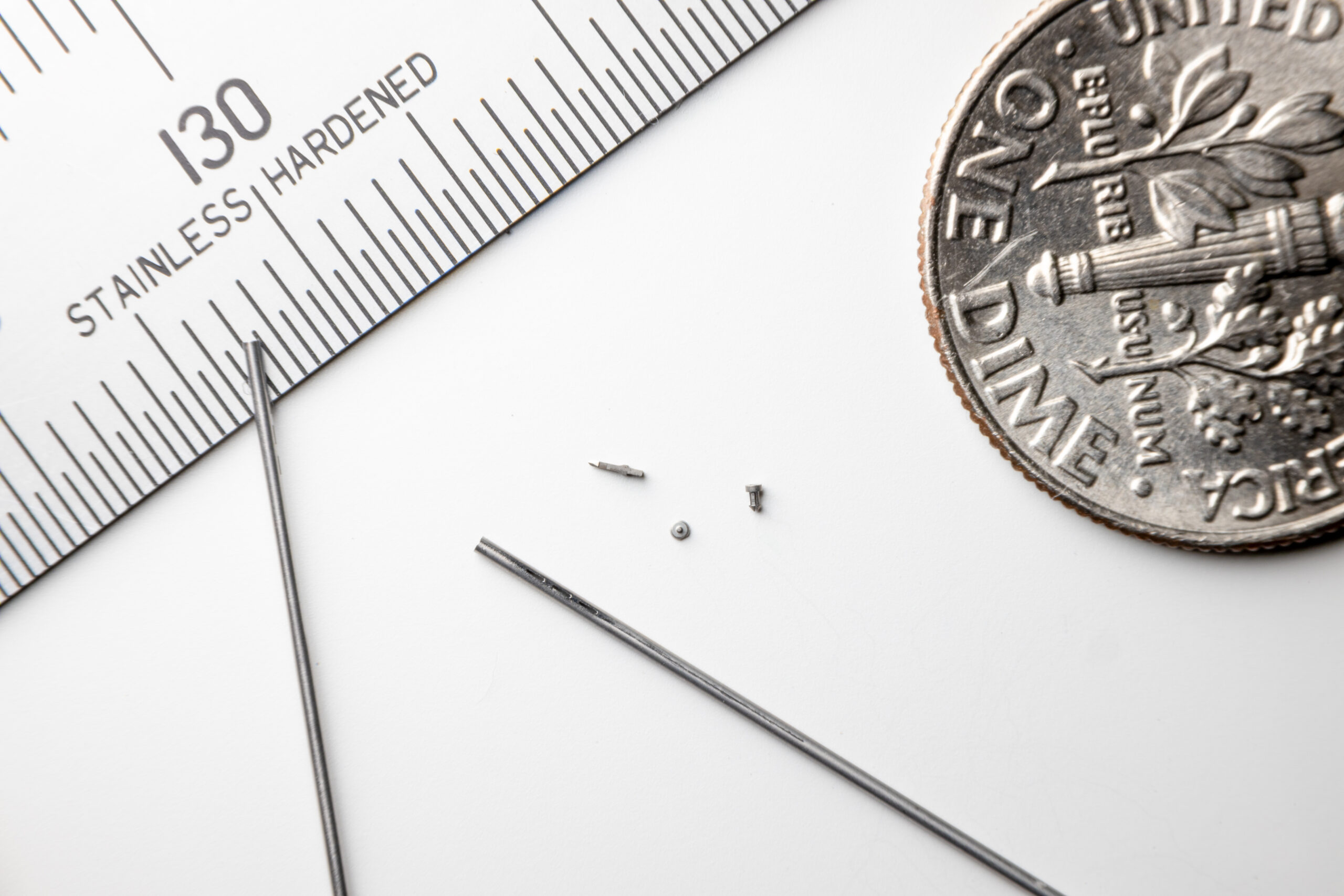

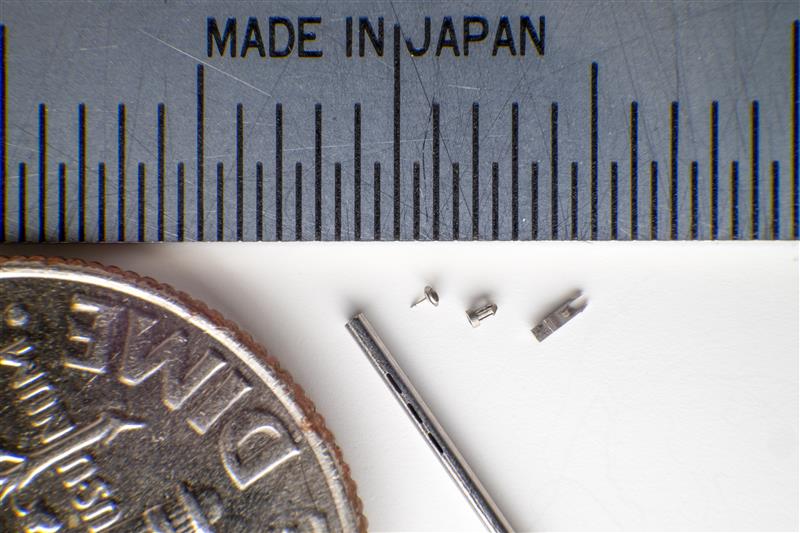

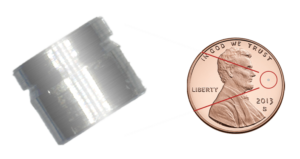

Customizable down to 0.3 cubic mm (0.00002 cubic in) and smaller.

Customizable down to 0.05mm OD, 0.03mm ID, SS304.

Customizable down to 0.001mm (0.00003947) in diameter.

From the customer’s point of view, we will continue to develop high-quality and satisfying products in order to create future high-tech products.

We will raise the level of quality awareness of all employees and ensure quality that will satisfy our customers.

We set “company-wide quality targets” and review them based on “quality activity plans and reports”.

We will constantly improve the effectiveness of our quality management system through quality activities.