CNC Lathe Manufacturing

High-precision CNC lathe machining, from prototyping to mass production.

Instant quotes on custom metal and plastic turned parts.

Quick-turn prototypes and production parts in days.

International prototype pricing includes tariffs.

ISO 9001:2015, ISO 13485

Next-Level extreme precision

propelling your designs into reality

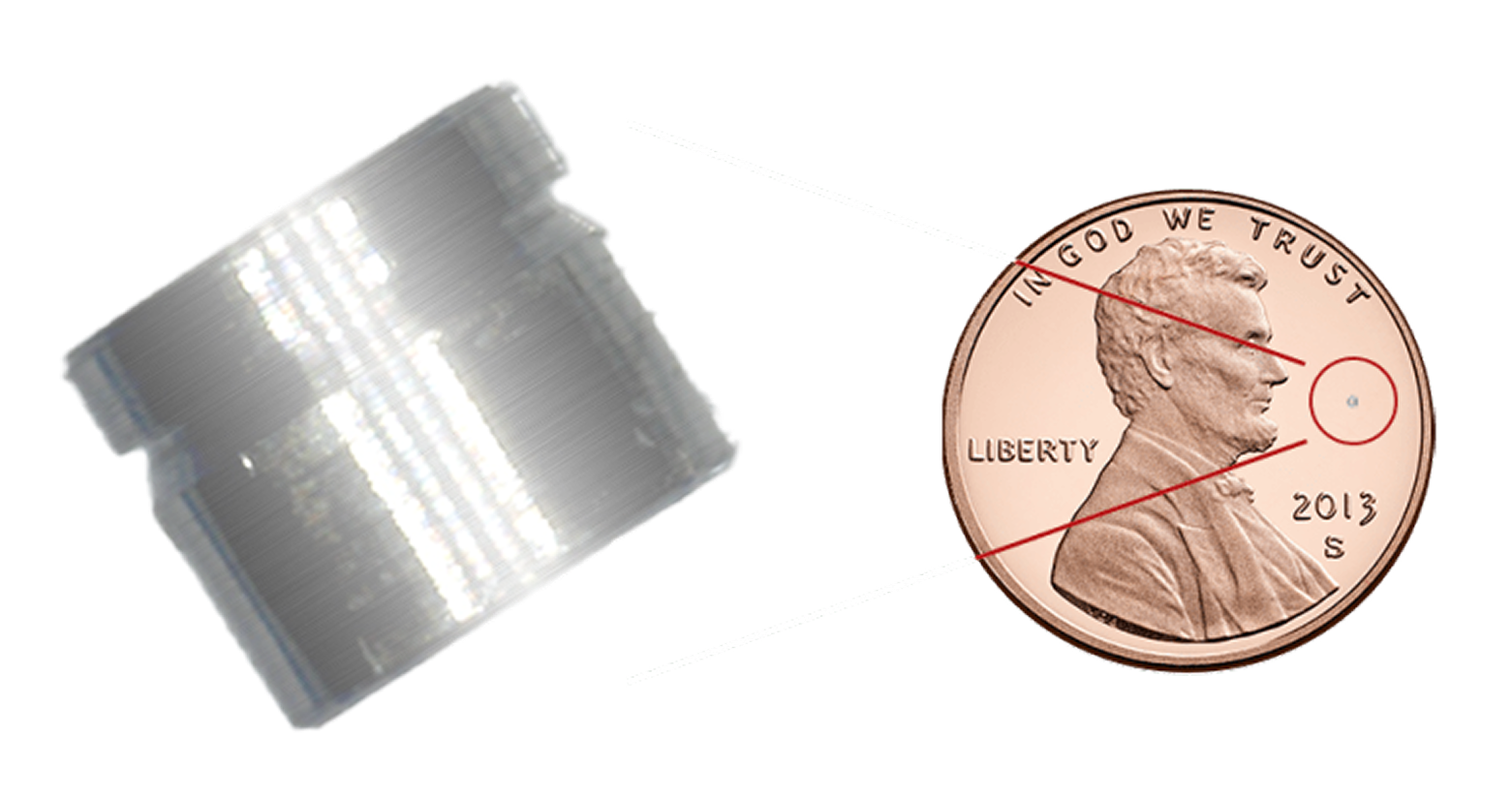

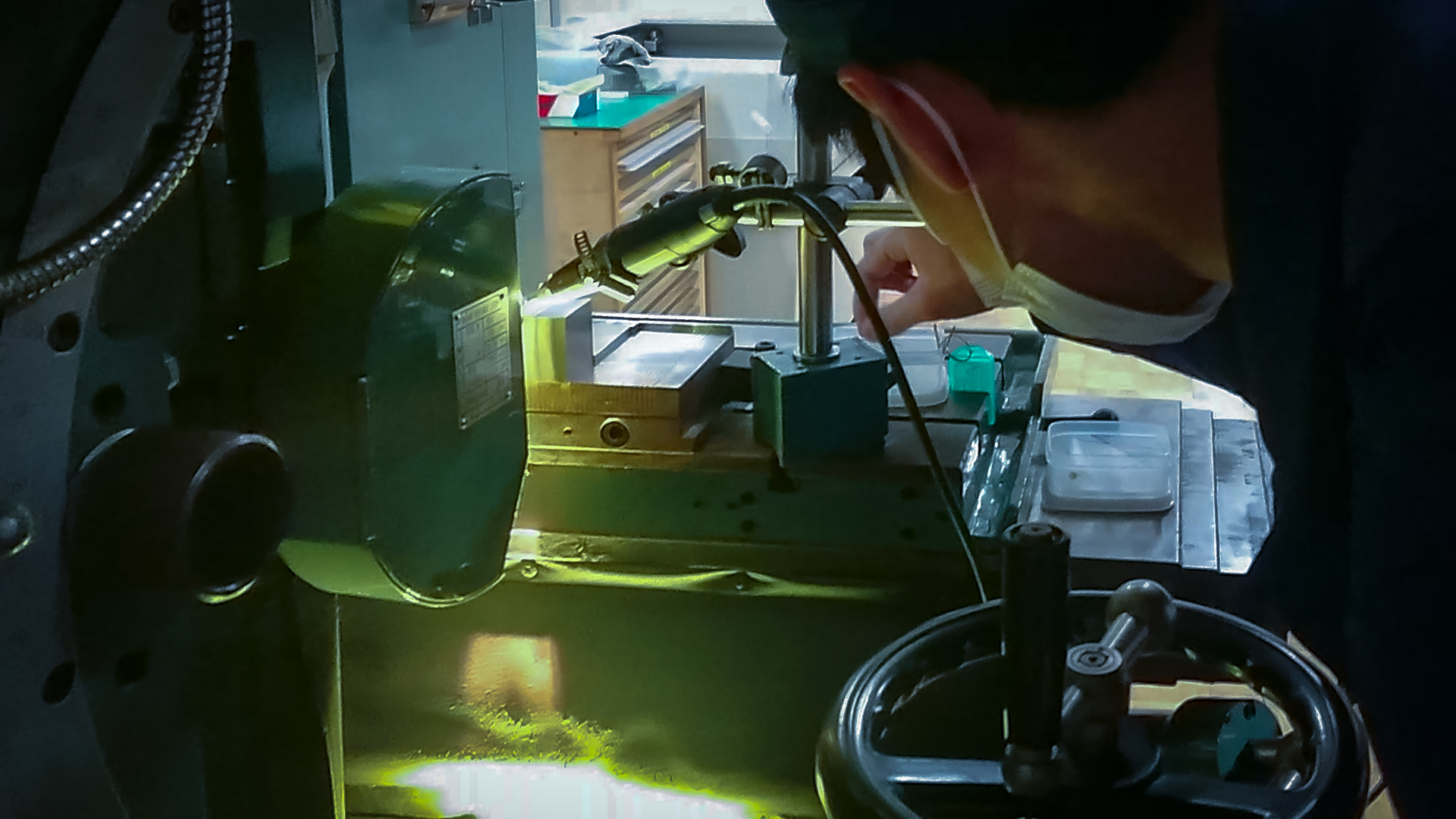

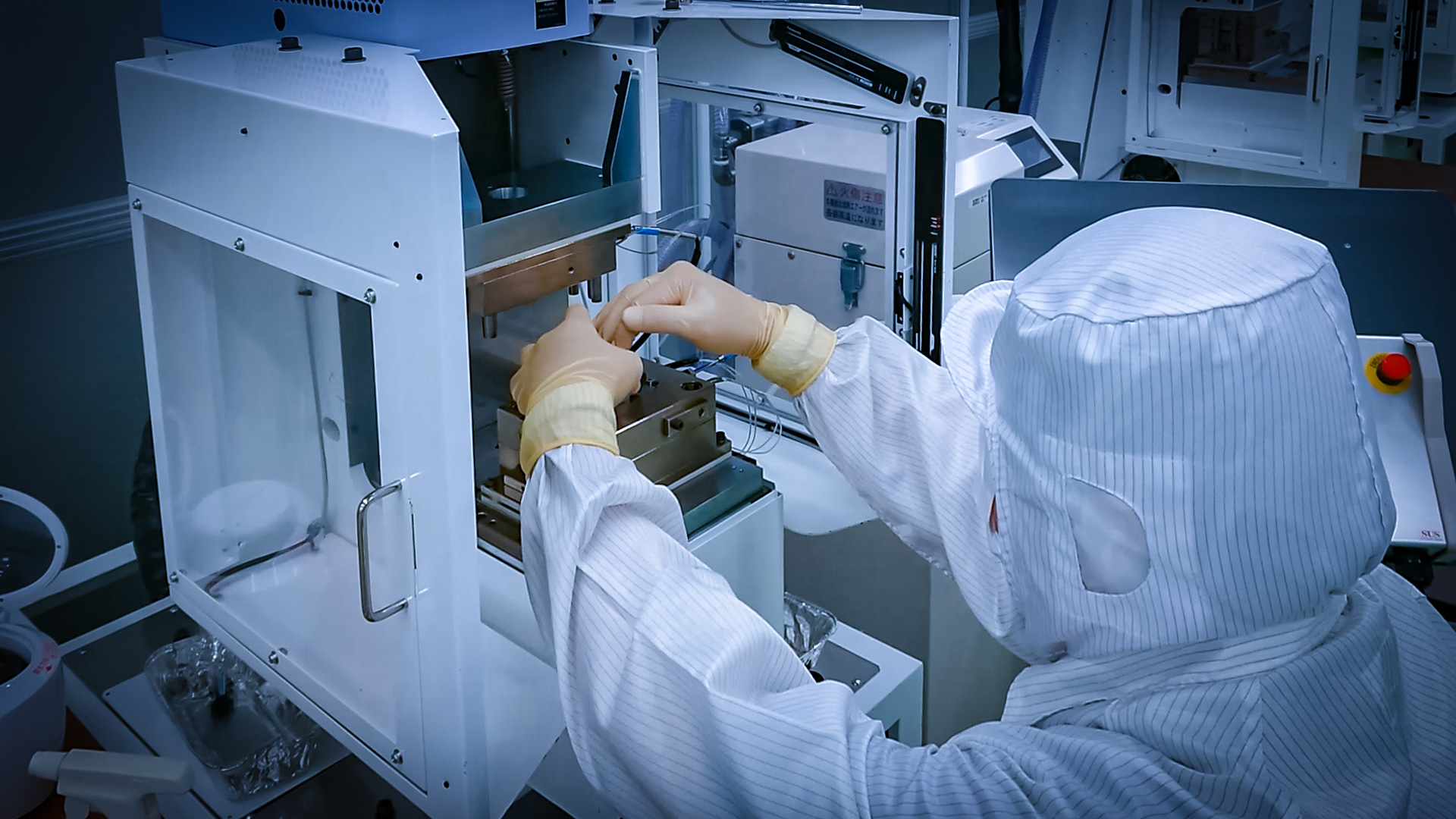

Advanced Micro Precision (AMP) specializes in ultra-precise CNC lathe machining for Class I, II and III micro medical components, devices, microelectronics, and semiconductors. Our ISO-certified Japanese manufacturing partners deliver sub-micron accuracy and complex geometries in clean room environments. Contact us to get started from design optimization and machining to quality inspection and on-time delivery, we handle every step for projects that demand extreme and miniaturization. Our suppliers also customize tools to meet the exact specifications of each customer’s parts.

Manufacturing with AMP

With access to a network including those with CNC lathes and turning centers,

AMP provides you with the capacity and capabilities your project needs,

while also delivering the most competitive pricing and lead times.

Our on-demand manufacturing platform can deliver high-quality metal and plastic CNC turning parts for rapid prototyping or low-to-high volume production runs.

CNC General Tolerances

Distance Dimensions

For features of size (Length, width, height, diameter) and location (position, concentricity, symmetry) tolerance as tight as +/- 0.0001 inches.

Orientation and Form Dimensions

Tolerance as tight as +/- 0.0001 inches, Angularity 1/2 degree.

Edge Condition

Sharp edges will be broken and deburred by default.

Critical edges that must be left sharp should be noted and specified on a print.

CNC Materials

Aluminum

Aluminum 2024-T3,

Aluminum 5052,

Aluminum 6061-T6,

Aluminum 6063-T5,

Aluminum 7050-T7451,

Aluminum 7075,

Aluminum 7075-T6,

Aluminum MIC-6,

Brass/Bronze

Brass 260,

Brass C360,

C932 M07 Bearing Bronze

Copper

Copper 101,

EPT Copper C110

Plastics

ABS,

Acetal [Delrin],

Acrylic,

G-10 Garolite,

Nylon 6/6,

PEEK,

Polycarbonate,

PTFE [Teflon],

Polyethylene,

Polypropylene,

Ultra-High Molecular,

Weight Polyethylene

Steel

Alloy Steel 4130,

Alloy Steel 4140,

ASTM A36,

Nickel,

Stainless Steel 15-5,

Stainless Steel 17-4 (SUS 630),

Stainless Steel 17-7 (SUS 631),

Stainless Steel 18-8,

Stainless Steel 303,

Stainless Steel 304,

Stainless Steel 310,

Stainless Steel 316/316L,

Stainless Steel 410,

Stainless Steel 416,

Stainless Steel 420,

Stainless Steel 430,

Stainless Steel 440,

Steel 1018,

Steel A36,

Tungsten Steel

Titanium

Titanium 6Al-4V,

Titanium Grade 2

Zinc

Zinc Sheet Alloy 500

Additional alloys and tempers are available upon request. We can source to your project specifications.

Finishes

As-Milled

The finish option with the quickest turnaround. Parts are left with visible tool marks and potentially sharp edges and burrs, which can be removed upon request. Surface finish is comparable to 125 micro inch Ra finish.

Bead Blast

The part surface is left with a soft, matte appearance.

Anodized (Type II Or Type III)

Type II creates a corrosion-resistant finish. Parts can be anodized in different colors—clear, black, red, and gold are most common—and are usually associated with aluminum. Type III is thicker and creates a wear-resistant layer in addition to the corrosion resistance seen with Type II.

Passivation (ASTM A967 / A380)

Enhance corrosion resistance and extend part life. Passivation strengthens the surface of stainless steel parts, helping them resist oxidation and chemical attack. Critical for medical and high-reliability applications.

Titanium nitride (TiN)

To increase hardness and wear resistance. TiN coating also improves lubricity, reduces friction, and gives parts a striking gold-like finish that highlights precision engineering.

Powder Coat

This is a process where powdered paint is sprayed onto a part which is then baked in an oven. This creates a strong, wear- and corrosion-resistant layer that is more durable than standard painting methods. A wide variety of colors are available to create the desired aesthetic

Custom

Don’t see the finish you need? Submit an RFQ and we’ll look into a finishing process for process for your custom lathe work.

Technologies & Facilities

CNC Milling Center

Shizuoka Tekko

VHR-AN20

CNC High Performance Lathe

TSUGAMI

SS20M-5AX,

T MA8H-YZ,

SS38MH-5AX,

B0126-III,

SS327-5AX,

S205,

B0206-III,

B0326-II

CNC EDM

MAKINO

EDNC32,

EDNC32H,

EDNC64

CNC Wirecut EDM

SODICK

AW453,

AP150,

AP200,

AP200L,

EXC100S,

EXC100L

CNC Profile Grinding

WASINO

GLS-135AS

CNC Jig Grinding

MITSUI SEIKI

3GBM,

300G

What Our Customers Say

Exceptional Turnaround and Service

They turned around our urgent order in record time without sacrificing quality. Their responsiveness and clear communication made the entire process smooth.

Fast, Friendly, and Accurate

Excellent experience from start to finish. The team is incredibly responsive, and the final product exceeded our expectations in terms of both quality and timing.

Great Support and Consistent Quality

They turned around our urgent order in record time without sacrificing quality. Their responsiveness and clear communication made the entire process smooth.